Nylon is a synthetic flexible plastic material. It is based on polyamides with extensive mechanical properties. It is used for 3D printing by various industries because of its versatile features.

Nylon filaments are considered to be more flexible and durable as compared to ABS or PLA filaments. Being a hydroscopic in nature is another property of nylon that helps it to absorb moisture. It is excellent for industries that require dyeing of the printed parts.

Let us check a few benefits of using nylon filaments for 3D printing.

Durable & Tough

Nylon filament is known for its toughness and durability. It has strong mechanical strength and less deformation. Nylon doesn’t snap or break easily. It also has extreme impact resistance property. Nylon filaments used in 3D printing generate sturdy parts that can resist shock.

Nylon produces thicker parts with higher density infill. On the other hand, while printing thinner parts, these filaments become flexible. Their tensile strength is also quite high. The flexible nature of nylon filaments used in 3D printing gives it much more toughness as compared to other materials. And this makes these filaments extremely durable and difficult to break. Moreover, they have low friction property and require less or no lubrication at all. Nylon is also known for greater chemical resistance that definitely allows more industrial applications.

Better Results

The quality of prints is better with nylon filament materials. With excellent layer adhesion property, the prints are extremely smooth and of high quality. Moreover, Nylon’s self-sealing property enhances the surface finish. Even the most complicated designs are well created using nylon. However, there are a few things that need consideration, including buying the filament from a reputable supplier and ensuring it is dry hasn’t absorbed moisture.

Unique & Easy To Use

3D printing with nylon filaments is very easy. Moreover, what makes the material more unique as compared to other materials used for 3D printing are its most versatile features. Nylon filaments do not require any heated-bed or cooling systems while printing. They are also considered to be the inexpensive 3D filament type.

Nylon is perceptive to humidity, therefore, the filaments are required to be kept in closed containers. Also, make sure to dry them before use as moisture can spoil the prints. However, it is because of this feature that nylon does not require the use of heated-bed during the printing process.

Today, nylon filament is one of the best options for 3D printing projects. It is strong and durable and helps to produce high-quality prints. The self-sealing property of nylon gives the prints a better surface finish. Other features mentioned above make it a reliable choice for many industries.

More commonly used nylon filaments for 3D printing are:

XSTRAND™ Glass Fiber Reinforced nylon GF30-PA6 – 1.75mm

Features

- Reinforced material

- Chemical and UV resistance

- High wear resistance

- High stiffness and strength

- Reduced warping effect

- Good layer adhesion

- Good operational temperature range

Nylon PA Filament – BLACK – 1.75mm

Features

- Durable material

- Tough and strong

- High tensile strength and elasticity

- Wrinkle-proof

- Abrasion and chemical resistance

- Used to print robust and heavy-duty components

Features

- High performance

- Lower moisture absorption

- High-quality prints

- Tough mechanical properties

- UV and Chemical resistance

- High fatigue endurance

- Dimensional stability

- Reduced warping effect

- Low friction

Alloy 960 Nylon – Carbon Fiber – 1.75mm

Features

- Extremely durable

- High-quality prints

- Reduced warping effect

- Strong filament

- Can visually mark layer lines

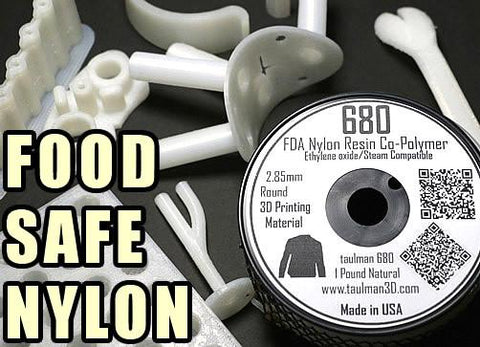

Nylon 680 FDA – Natural – 2.85mm

Features

- Extremely durable

- High-grade pure polymer

- Less pliable

- More transparent

- Extreme clarity levels

If you are looking for nylon filament for 3D printing, we can help. We carry an extensive range of nylon filaments, including 2.85mm and 1.75mm filament. Browse through our selection, and buy online with us now! You can call us at 905-677-1337 if you have any questions.